Dorian Derežić - 07/02/2024 | 15 min read

SpaceTime Research and Development Automotive

In an industry defined by innovation and progress, performance optimization has emerged as a critical factor in automotive research and development (R&D).

As vehicle technologies continue to evolve, so do consumer expectations. Today's drivers demand vehicles that not only offer high levels of comfort and convenience, but also exceptional performance across diverse conditions.

R&D departments play a crucial role in meeting these demands, and their task is far from straightforward. Vehicles must perform optimally in various geolocations, weather conditions, and traffic patterns. With the rise of Advanced Driver Assistance Systems (ADAS) and autonomous vehicles, the performance matrix has become even more complex.

Performance optimization in this context is about more than just enhancing speed or fuel efficiency. It involves fine-tuning vehicles to perform efficiently under specific conditions, ensuring that safety and user experience are maximized. Understanding these nuances and making the necessary adjustments is pivotal for OEMs that want to stay ahead of the competition. It's a challenging task, but with the right tools, it becomes much more manageable.

One such tool designed to tackle this challenge head-on is Mireo SpaceTime. Designed as a powerful big data platform for connected vehicles, SpaceTime brings a whole new level of detail to vehicle data analysis – offering real-time, granular insights into how vehicles perform under diverse conditions.

By leveraging spatio-temporal data, SpaceTime enables automotive OEMs to study and understand how different factors like location, weather, or traffic patterns impact vehicle performance. It's about delivering an unrivaled level of insight, providing OEMs with a clear picture of performance variations and correlations.

The value of such detailed insights is immense, allowing OEMs to tailor vehicle design, engineering, and tuning to specific regions or driving scenarios. This region-specific performance optimization opens up new frontiers in vehicle R&D, offering a powerful tool for creating vehicles that meet and exceed driver expectations no matter the circumstances.

Spatio-temporal data analysis is an advanced approach that enables an understanding of how different factors interact and evolve over both space and time. Mireo SpaceTime empowers OEMs with this level of sophisticated data analysis, revealing unique performance insights that static or single-variable analysis might miss.

With spatio-temporal analysis, automotive OEMs can examine vehicle performance variations over different routes, across different seasons, or during various times of the day. This provides a rich, multidimensional view of performance, allowing R&D teams to pinpoint issues or opportunities that only manifest under specific spatial and temporal conditions. For instance, performance issues that arise only during high-speed highway driving at night, or the outstanding performance of a particular model in hilly terrains during winter.

When it comes to automotive performance, there's no such thing as a 'standard' driving condition. Different geolocations come with unique road characteristics, weather patterns, and traffic behaviors. Therefore, a vehicle's performance profile is heavily influenced by these factors.

With the help of Mireo SpaceTime, OEMs can evaluate how each of these factors affect vehicle performance. For example, a vehicle’s fuel efficiency could vary between urban stop-and-go traffic versus open highway driving. By correlating geolocation and traffic data with vehicle telemetry, manufacturers can gain a deeper understanding of their vehicles’ strengths and weaknesses in varying real-world conditions.

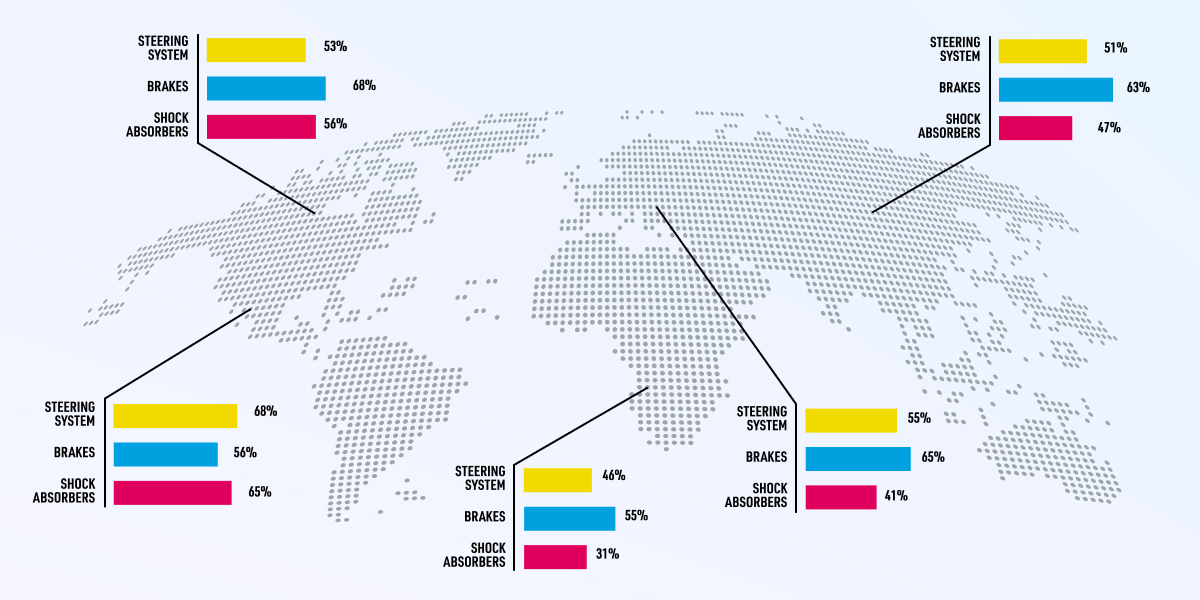

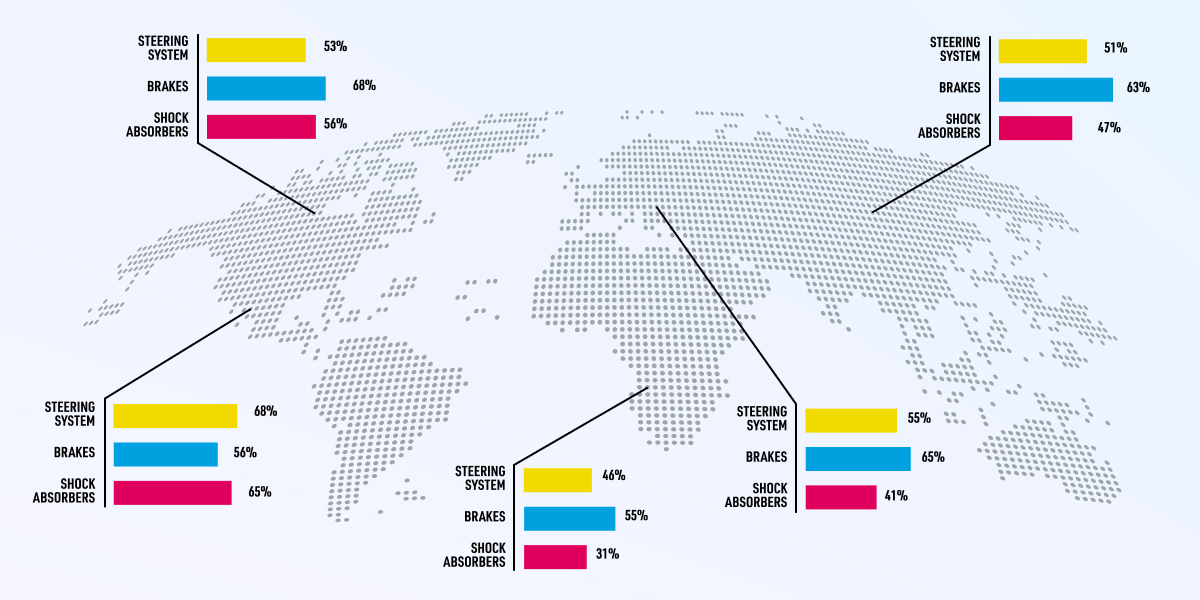

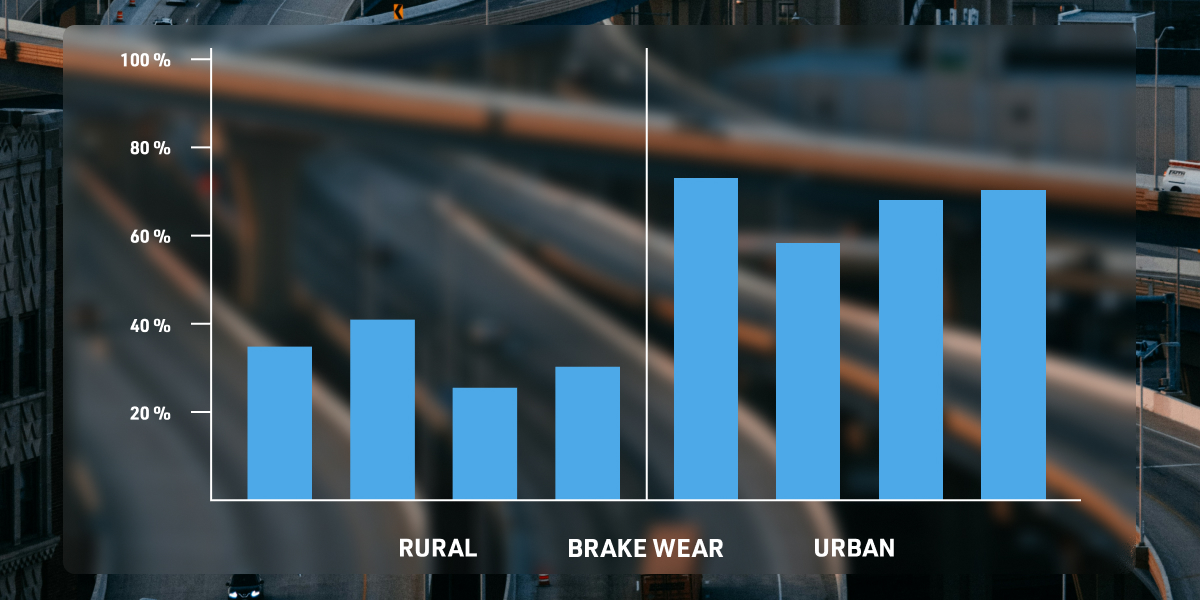

Mireo SpaceTime’s advanced data analytics capabilities go beyond mere data collection to provide actionable insights from complex datasets. It enables R&D teams to identify performance correlations that are not immediately apparent. For instance, it could reveal that brake wear is unusually high in models driven frequently in certain geographies, indicating a correlation between terrain characteristics and brake system performance.

These insights allow manufacturers to make informed decisions about vehicle design, such as improving the brake system for those specific models or even developing region-specific variants. It also aids in proactive maintenance by informing vehicle owners when to expect certain part replacements based on their driving conditions and patterns.

By combining data analysis with machine learning algorithms, Mireo SpaceTime can forecast vehicle performance under different conditions. These predictive models are built using historical data and are continuously refined as more data is collected.

For instance, a predictive model could forecast the likely deterioration of a vehicle’s battery performance in extreme cold weather, even before the vehicle has been exposed to such conditions. This allows for preemptive actions, such as informing customers about potential issues or refining the vehicle design for better resilience.

In essence, the integration of data analysis and machine learning gives OEMs the ability to look into the future, predict potential performance issues, and devise solutions before problems even occur, radically transforming the R&D landscape in the automotive industry.

Consider, for instance, the case of electric vehicles (EVs). Battery performance in EVs is highly susceptible to extreme temperature conditions. With SpaceTime, manufacturers can analyze the real-world data of EVs operating in cold regions. This data can provide insights into how battery performance is affected at different temperature levels and how much range reduction an EV owner might experience during winter months.

Using this analysis, manufacturers can fine-tune their battery management systems to better cope with cold weather, optimize the heating, ventilation, and air conditioning (HVAC) systems to reduce energy consumption, or even innovate better thermal insulation techniques. Similarly, analysis of data from hot regions can guide the optimization of cooling systems in EVs. Such insights help manufacturers build more resilient and reliable EVs, which can drastically improve customer satisfaction and adoption rates.

Another key area where SpaceTime's regional analysis could be a game-changer is in vehicle suspension systems. Roads in some regions may be predominantly rough or uneven, causing significant stress on the vehicle suspension and potentially resulting in a less comfortable ride.

By analyzing data from vehicles operating in such regions, manufacturers can uncover detailed insights about the impact of these conditions on vehicle suspension systems. They can then use these insights to tune the suspension system to better handle these conditions, thereby ensuring a smoother ride for the end-user. This would not only enhance the driving experience but also potentially increase the longevity of the vehicle components, reducing maintenance costs for the end-users and boosting the brand's reputation for durability and performance.

Let's delve into the realm of autonomous and semi-autonomous vehicles to exemplify the potential of this approach. Analyzing driver behavior in real-time can aid the development of advanced driver-assistance systems (ADAS) that can adapt to individual driving styles. For instance, if a driver tends to keep more distance from the car in front compared to the average driver, the vehicle's adaptive cruise control system can learn and adapt to maintain this preferred distance.

Such adaptive systems can make the driving experience more personalized and comfortable. Additionally, it can increase the acceptance and trust in autonomous technologies, a critical factor in the widespread adoption of these technologies.

The benefits of incorporating real-world performance data in testing processes can be multi-faceted. Let's consider a manufacturer developing an advanced traction control system for their vehicles. Traditionally, they would test this system under various simulated conditions. However, real-world data might reveal that a significant number of traction control engagements happen during heavy rains on a specific type of road surface.

With SpaceTime, the manufacturer can integrate these specific conditions into their testing processes. This not only ensures that the system is robust in real-world scenarios but also builds confidence in the product's performance amongst stakeholders, including regulators, investors, and customers. Thus, SpaceTime's data-driven approach can significantly enhance the credibility and reliability of the testing process, giving a competitive edge to the manufacturers.

By enabling more accurate and realistic test scenarios, SpaceTime can help OEMs reduce their dependence on physical testing, which can be time-consuming, resource-intensive, and environmentally unfriendly. This ultimately leads to a more efficient and sustainable R&D process.

Performance optimization through SpaceTime’s granular data analysis can be an effective tool in fostering innovation and staying competitive. Automotive companies operate in a rapidly evolving landscape where technological advances are continually shifting customer expectations and market dynamics. The ability to optimize vehicle performance based on precise, real-time insights can fuel innovation in multiple ways.

Firstly, it empowers OEMs to tailor vehicle design, engineering, and tuning to specific conditions, thus going beyond the 'one-size-fits-all' approach and offering more personalized, efficient, and high-performing vehicles. This kind of innovation can give OEMs a unique selling proposition and help distinguish their offerings from competitors'.

Secondly, the analysis of performance data can uncover patterns and correlations that can lead to breakthrough innovations. For instance, the data might reveal that certain vehicle components perform differently under specific weather conditions. These insights can drive the development of new components, materials, or technologies to enhance performance under such conditions, thus resulting in innovative products that meet and exceed customer expectations.

A vehicle’s performance has a direct impact on the customer’s driving experience, and consequently, their satisfaction and trust in the brand. When customers know that their vehicle has been designed and engineered to perform optimally under their specific driving conditions, they feel valued and understood. This kind of customer-centric approach can significantly enhance customer satisfaction.

Moreover, vehicles that perform well under different conditions are likely to be safer and more reliable, which can strengthen customer trust. This is especially crucial in the context of advanced driver-assistance systems (ADAS) where safety is paramount. By using SpaceTime to optimize the performance of these systems under various conditions, OEMs can assure customers of their commitment to safety, thus earning their trust.

Performance optimization has several implications for cost management in automotive R&D. Firstly, it allows for more efficient use of resources. By analyzing real-time performance data, manufacturers can identify and focus on the areas that need improvement, instead of investing resources across the board. This targeted approach can lead to significant savings in R&D costs.

Secondly, performance optimization can reduce the cost of errors and rework. By identifying issues early in the development process, manufacturers can make necessary adjustments before these issues escalate into major problems that are costly to fix. Moreover, by continually monitoring performance data, they can ensure that their solutions are effective, thus avoiding the expense of repeated iterations.

Performance optimization is not just about improving existing products; it can also lead to the discovery of new revenue streams. As manufacturers analyze performance data, they may uncover unmet needs or opportunities in the market. For example, the data might reveal that vehicles in certain regions are often exposed to extreme weather conditions. This could lead to the development of specialized vehicles or features for these regions, creating a new product line and a new source of revenue.

Additionally, the insights derived from performance data can be used to offer value-added services. For instance, predictive maintenance services, which use performance data to predict and prevent vehicle issues, can be a significant source of revenue. Not only do these services provide additional income, but they also enhance customer satisfaction and loyalty by ensuring that their vehicles are always in top condition.

Performance optimization through SpaceTime can therefore be a strategic tool for growth and profitability, opening up new avenues for revenue generation while also enhancing the value of existing offerings.

The most pivotal technical advantage of Mireo SpaceTime is its capability to perform granular data analysis in real-time. This detailed level of analysis enables R&D teams to observe minute performance shifts, identify underlying patterns, and draw accurate conclusions. The ability to make decisions based on this level of precision can significantly boost the efficiency of the R&D process.

By providing a comprehensive view of vehicle performance under various conditions, SpaceTime allows R&D teams to make data-driven decisions that can directly impact the quality, safety, and efficiency of vehicles. This can result in the development of vehicles that are finely tuned to specific conditions, thus enhancing performance and customer satisfaction.

In the fast-paced world of automotive technology, adaptability is key. The ability of R&D processes to evolve and keep pace with technological advancements and changing market dynamics can significantly impact an OEM's competitiveness.

Mireo SpaceTime’s granular performance data analysis can inform an OEM’s strategic planning, helping them to adapt to shifts in technology and market demands. This capacity to adapt and evolve based on solid data insights ensures that R&D remains relevant and effective, even as conditions change.

Efficient resource allocation is fundamental to the success of any R&D project. By analyzing granular performance data, SpaceTime can help identify the areas of vehicle design, engineering, or tuning that require the most attention and resources.

This informed approach to resource allocation can maximize R&D productivity and minimize wastage, leading to a more efficient and cost-effective R&D process. By directing resources where they are needed the most, R&D teams can address performance issues more effectively and deliver high-quality results.

As the automotive industry shifts towards sustainability, R&D processes must align with these objectives. Performance optimization with Mireo SpaceTime can contribute significantly to these efforts.

For instance, by optimizing vehicle performance, manufacturers can reduce fuel consumption and emissions, thereby contributing to environmental sustainability. Additionally, efficient resource allocation can minimize wastage in the R&D process, further enhancing sustainability.

Moreover, the insights derived from performance data can inform the development of eco-friendly vehicles. For example, data on how vehicles perform under different conditions can guide the design and engineering of electric vehicles or hybrid models, thus supporting the industry’s transition towards sustainable mobility.

In these ways, Mireo SpaceTime not only enhances the technical efficiency of R&D but also contributes to the broader sustainability goals of the automotive industry.

The landscape of automotive R&D is evolving at an accelerated pace, driven by rapid technological advancements and changing consumer expectations. In this dynamic environment, the need for performance optimization is more critical than ever. By analyzing vehicle performance data at a granular level and across various conditions, OEMs can fine-tune their designs and engineering processes to better meet market needs.

In essence, the ability to harness performance optimization not only facilitates the development of vehicles that are highly attuned to specific conditions but also fosters innovation and competitive advantage. As such, performance optimization is poised to play an increasingly central role in shaping the future of automotive R&D.

In this context, Mireo SpaceTime emerges as a pivotal player in driving R&D optimization in the automotive industry. With its advanced capabilities to analyze granular vehicle data in real-time, SpaceTime enables OEMs to uncover detailed performance insights and identify areas for optimization.

The benefits of leveraging SpaceTime's performance optimization capabilities extend beyond technical improvements. They also include significant business advantages such as enhanced innovation, improved customer satisfaction, cost management, and the discovery of new revenue streams.

Furthermore, SpaceTime's contribution to sustainable R&D processes is particularly noteworthy, given the growing focus on sustainability in the automotive industry.

In conclusion, Mireo SpaceTime represents a transformative force in automotive R&D, offering a comprehensive suite of capabilities that can unlock new levels of performance optimization and business success for OEMs. As the industry continues to evolve, the role of tools like SpaceTime in propelling this evolution will undoubtedly grow, underscoring the importance of harnessing data-driven insights in automotive R&D.